Final Project

- fernanda villalobos

- May 1, 2019

- 3 min read

For our final project we had the opportunity to make something using digital fabrication/tools. In Lab 4, I presented my idea which was to make a Jack in the Box inspired toy.

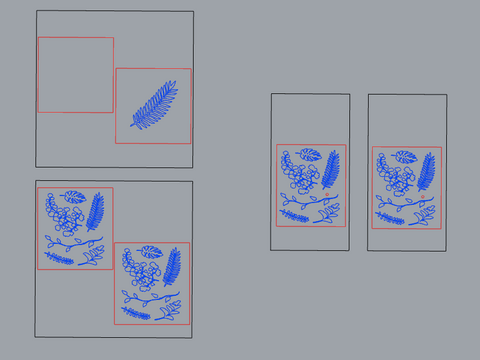

The first step of this process was to purchase my wood, I used Birch Plywood because it had worked very well in a past lab so I decided that it was the best option. I created a box in Rhino and duplicated the edges so I could get the outlines that would later be used for laser cutting. Something I didn't include in lab 4 and ended up adding to my final project were the leaf engravings on the sides of the box. I thought the box was a little too simple without the engravings.

A mistake that I made during the process of creating my final project was the placement of the holes. Two pieces of wood needed small holes but I failed to realize that the holes needed to be mirrored. I fixed the mistake by having the laser cutter engrave the design on the other side.

I purchased a Jack in the Box and used the spring that was inside for my final project, I also 3d printed the giraffe that I modeled in Lab 4. I unfortunately do not have pictures of the giraffe being printed. I purchased joint compound and coated the giraffe in a few even layers. Once it was dry I sanded the giraffe and spray painted it yellow.

The other materials I needed for my final project were the parts inside the box which would make it work similar to a jack in the box. I modeled those parts in Lab 4 but then changed them a little to fit with the new dimensions of the box.

Below are pictures of the spinning wheel, handle knob, and hooks that were used inside the box.

When the box is closed, the grey hook is holds down the lid with the yellow hook, they match up together. The handle spins the wheel and the triangle attached to the wheel tilts the grey hook back which causes the yellow hook to be released and the spring opens the box. The rubber bands were added to keep the grey hook in place after it is titled. The pictures also show the spring. The spring needed to be nailed down with this rectangle shaped piece of metal to keep it in the middle of the box.

Below are images of my final project, digital fabrication was very helpful and useful when creating my project. The laser cutter made sure that the sides of my box would fit together and it also added some detailed engravings to the box. The 3d printer was also very useful in creating parts for the internal mechanism. I could not purchase these parts because I needed them to be a certain size and look specific way. Something I would change would be the appearance of the box. I sanded most of the burnt edges away but if I could go back I would sand the box more and possibly also stained it too. Something else I would improve would be the time it takes for the box to open, it only takes one spin and I would of liked it to take a bit longer. Overall, I am happy with the final product.